What is powder coat? As the name suggests, the paint is in powder form, which is coated on the metal surface. Some recent developement have deviced a complex process to paint on high density fibreboard better known as HDF. The process was invented by Daniel Gustin in 1940s, the main benefit of the paint is the durability it gives while making a symmetrically smooth layer. However its an industrial process and cannot be done on a small scale or n a DIY manner. The typical thing in this process is that where we are mostly familier with NC based, turpinetine based, thinner based paints; there is no solvant involved in powder paint process. It is bonded with heating.

Process:

Process of sand blasting. The sand is blasted via air pressure which is created via an air compressor.

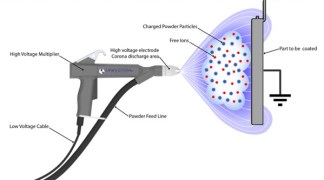

2. Then the powder which is thermoplastic or thermoset polymer (for sun friendly finish, outdoor powder coat.), which is applied by a gun which throws the charged powder on the metal, there is no solvent present,

3. To bond the powder to the metal surface the piece is further cured by typically heating it to 150 to 200 degree Celsius in a closed environment to avoid any impurities to seep in the product is then cooled down to room temperature.

Typical Oven Used For Powdercoating.

This process makes a fine coat over the metal with thickness of around 30 to 80 micron. Depending on how thick the powder was initially.

Advantage of Powder Coat Paint

Disadvantages of Powder Coat Paint