What is powder coat? As the name suggests, the paint is in powder form, which is coated on the metal surface. Some recent developement have deviced a complex process to paint on high density fibreboard better known as HDF. The process was invented by Daniel Gustin in 1940s, the main benefit of the paint is the durability it gives while making a symmetrically smooth layer. However its an industrial process and cannot be done on a small scale or n a DIY manner. The typical thing in this process is that where we are mostly familier with NC based, turpinetine based, thinner based paints; there is no solvant involved in powder paint process. It is bonded with heating.

Process:

Process of sand blasting. The sand is blasted via air pressure which is created via an air compressor.

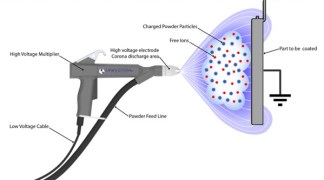

2. Then the powder which is thermoplastic or thermoset polymer (for sun friendly finish, outdoor powder coat.), which is applied by a gun which throws the charged powder on the metal, there is no solvent present,

3. To bond the powder to the metal surface the piece is further cured by typically heating it to 150 to 200 degree Celsius in a closed environment to avoid any impurities to seep in the product is then cooled down to room temperature.

Typical Oven Used For Powdercoating.

This process makes a fine coat over the metal with thickness of around 30 to 80 micron. Depending on how thick the powder was initially.

Advantage of Powder Coat Paint

Disadvantages of Powder Coat Paint

FAQs

Powder coating is a dry finishing process where powdered paint (usually a thermoplastic or thermoset polymer) is electrostatically applied to a metal surface and then cured under heat to form a smooth, durable, and uniform coating.

Unlike traditional liquid paints that use solvents, powder coating contains no solvents. It's applied as a dry powder and cured with heat, making it more durable and environmentally friendly.

No, powder coating is an industrial process that requires specialized equipment like sandblasting chambers, electrostatic spray guns, and curing ovens. It's not feasible for small-scale or home DIY use.

The process involves:

Surface preparation via sandblasting to clean and smoothen the metal.

Application of powder using a spray gun that electrostatically charges the powder.

Curing the coated object in an oven at 150–200°C to bond the powder to the surface.

Primarily metals are powder coated. However, newer technologies allow for powder coating on HDF (High-Density Fibreboard) as well, though it's more complex.

Long-lasting and durable finish

Smooth, drip-free application

Environmentally friendly – no harmful fumes

Scratch-resistant and ideal for outdoor furniture (e.g., using Pure Polyester variant)

Thicker coating than conventional paint

Cost-effective in the long run

High initial setup cost

Difficult to repair or touch up if chipped

Limited color choices unless ordered in bulk

No re-painting possible once the surface is powder coated

The final powder-coated finish usually has a thickness of 30 to 80 microns, depending on the powder used and application process.

The modern powder coating process was invented by Daniel Gustin in the 1940s.

Sandblasting removes rust, oil, old paint, and impurities from the metal surface, ensuring better adhesion of the powder and a smoother, cleaner finish.